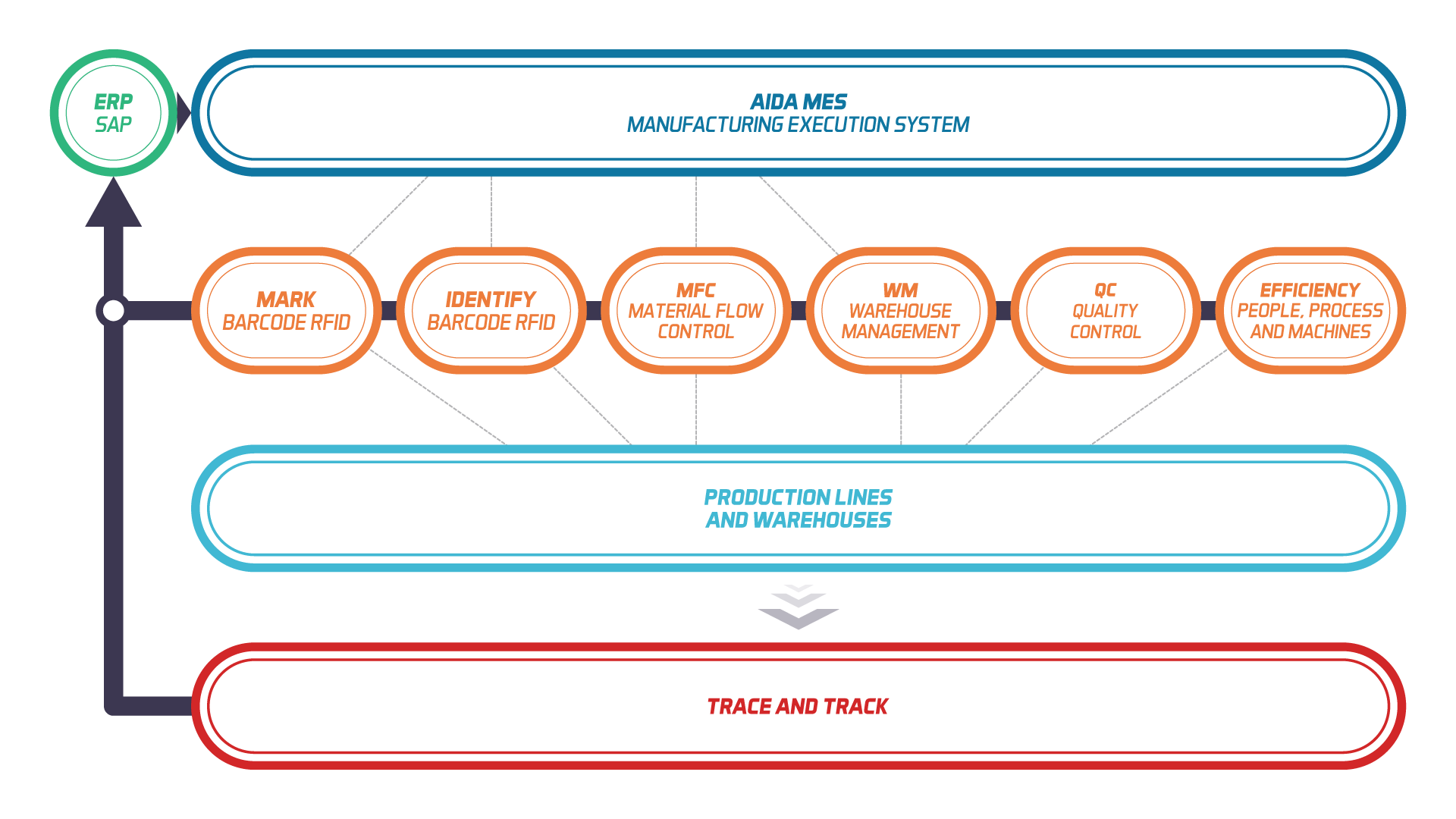

AIDA is unique system that integrates industrial machines, production processes and data transmission with ERP systems like SAP or other leading providers.

The identification module offers:

- Raw materials identification according to internal marks or standard GS1 marks (like SSCC)

- Container identification in production process (RFID)

- Final product identification (in production, warehousing or distribution)

- Machine identification

- Operater identification

- Process or operations identification

- Server based identification management and execution

- ERP integration (SAP or other custom integration)

Automation of quality control, connection with metering equipment (LIMS)

Providing tools for:

- Product and material marking

- Easy control of storage and movement of materials within warehouse

- Processing of transactions of materials which includes shipping, receiving, put-away and picking

- Location management FIFO/LIFO/FEFO product flow management

- Year-end, and partial inventory

- Share information with business systems (SAP or other)

The MFC module is fully integrated part of the AIDA software suite , and it is responsible for material flow control of raw material or semi-finished goods consumption by serial number or batch.

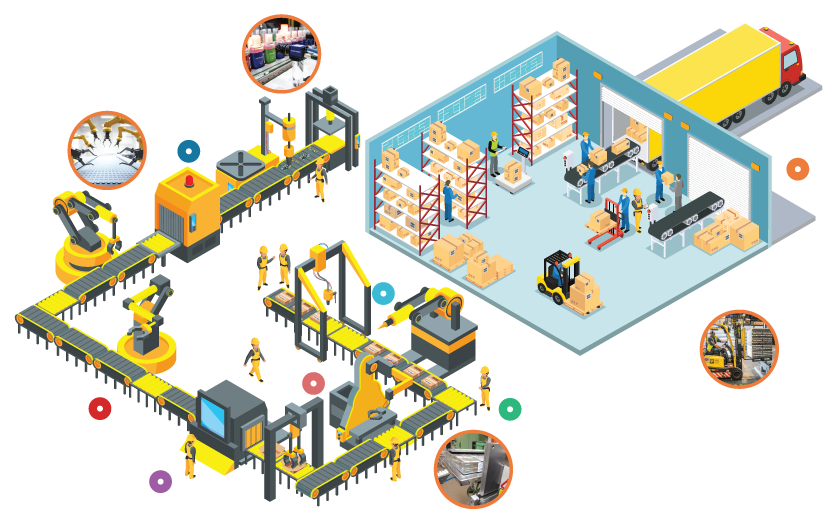

Codels manufacturing Trace and Track solutions allow the customer to run a fully connected, real-time supply chain. From the plant floor and warehouse operations right through to distribution with agility, traceability and visibility on goods, people, assets and events. Whether the driver is compliance with the latest traceability standards, to minimise inventory, manage supplier performance or meet stringent just-in-time schedules, Codel will help you.

Cilj Industrije 4.0 pametna su poduzeća, tvornice i pogoni koji su prilagodljivi i učinkovito integriraju klijente i ostale poslovne partnere (dobavljače, kooperante) u jedinstvenom procesu što bržeg i usklađenijeg, a posljedično efikasnijeg procesa konverzije inputa u output, bez obzira o kojoj se djelatnosti. Radi se o povezivanju strojeva, uređaja i senzora (Internet of Things) radi optimizacije procesa.

CONTACT DETAILS

CONTACT US